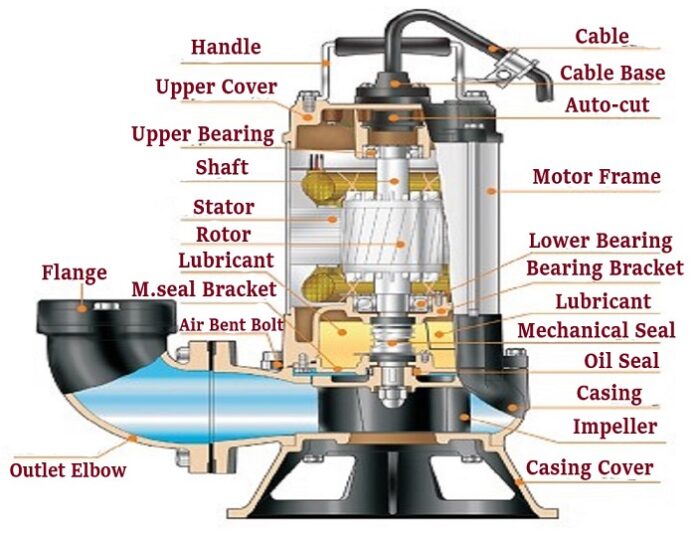

The submersible pump (or electric submersible pump (ESP)) is a fully sealed device with a motor and connected to a pump housing. The entire structure is immersed in the pumped liquid. It is a famous type of the centrifugal pump. The submersible sump pump is a pump that can be submerged and still achieve the desired efficiency. These pumps push water to the surface instead of pumping water from the ground, like jet pumps.

The underwater series pumps are vertically submerged and driven by electric motors. Connect the pump body and motor. To transport solid particles containing waste, sand, coal ash, tail, and groundwater or to obtain hot water for irrigation and municipal water use.

Working Principle of Submersible Pump

- The submersible pump uses as a multistage centrifugal pump that works vertically. Although its structure and operational characteristics have undergone constant changes in recent years, the basic operating principles have remained the same.

- The liquid produced by the huge centrifugal force generated by the rapid rotation of the impeller loses its power is transformed into pressure energy in the diffuser.

- The pump shaft links to the installation site via a mechanical connection under the pump. The well fluid enters the pump through the inlet plate and discharge by the pump outlet.

- Other components include radial bearings (bushing) distributed along the shaft to support the radial shaft support of the high-speed rotary pump.

- The optional thrust bearing supports some of the axial force produced in the pump. But most of the force absorbs by the thrust bearing in the shroud.

Types of Submersible pumps

1) Deep well pump

Deep well submersible pump is a widely used submersible pump. These pumps can also use for urban uses. The main body of these pumps connects with the motor to work underwater. It has simple repairs and impact plan rebuilding. When these pumps come into operation, they must be completely submerged in water.

2) Stainless Steel Pumps

Stainless steel pumps are better than cast iron pumps. They are fully coated in stainless steel and have a high resistance to acids. In these types of pumps, replace warm water or slightly acidic water often. A water source such as a well can protect by its unique jets and freshwater can flow frequently. The whole pump can immerse in water while working.

3) Bottom suction pump

Low-suction pumps are widely used in lakes, landmines, swimming pools, and rivers. These types of bombs use for emergency and expedition applications. These pumps have an easy than other types of pumps

4) Oil Filled Pumps

Submersible oil-filled pumps use oil immersion motors. These pumps are widely used in water extraction, agricultural irrigation, mountain irrigation, water supply, and industrial supply and drainage systems, mountain water supply, etc. The engine heater must be cooled to cool down. It can use in cold regions because the oil cannot freeze. They are very simple and easy to install and modify. These pumps can supply clean water such as that of a lake, swimming pool, or river.

Check out: What is a Reciprocating Pump? Working and Types

5) Water chiller Pump

These submersible pumps are commonly used in industry, agricultural land irrigation, residential water, and other agricultural businesses. They can also use underwater as a complete bomb. The engine, a floating water cooler, can be configured for underwater work

Applications of Submersible Pump

- The pump shaft connects to the station via a mechanical link under the pump. Fluid from the well enters the pump through the inlet plate and is lifted by the pump stage.

- Other components include radial bearings (bushings) distributed along the shaft to support the radial shaft support of the high-speed rotary pump.

- The optional thrust bearing supports some of the axial force produced in the pump, but most of the force is absorbed by the thrust guard.

- Efficiency – Compared to conventional pumps, submersible pumps are better because the liquid pump is close to the pump. So, it doesn’t work like normal bombs.

- Sound level: underwater pumps rarely make less noise because they are immersed in water. The tank wall helps reduce the noise produced by the pump. Conventional pumps are located outside of wells or manifolds which can make a lot of noise.

- Safety: Compared to other types of pumps, these pumps are quite safe because all potentially dangerous parts of the pump are submerged. It is usually covered and children are less likely to manipulate internal components and valves.

Advantages

- These pumps are very efficient

- A lot of energy can be saved

- Handling of solids and liquids

- These pumps are quiet on the water

- These pumps are versatile

- There is no need to start

- Excellence

- Internal pressure is sufficient to pump internal water and no additional components are required

- These pumps have no cavitation problems.

Disadvantages

- Over time, the pump seal breaks.

- Pay attention to the overheating of the pump motor.

- Does not apply to all applications.

- These pumps are difficult to identify and damage such as cracks can be repaired.

- Expensive due to mechanical properties

- Since the submersible pump is sealed, the gasket will rust over time. Therefore, water can enter the engine and damage the equipment.

- Repair of complex systems

- Each use requires different types of bombs and one bomb is not enough for all purposes.

- If it is not fully submerged, extensive damage will occur.