The introduction of technology in the manufacturing industry has been instrumental in the overall quality of output. Many companies have embraced new techniques to improve their production processes to meet customer demands. Metal 3D printing is an industrial manufacturing technique that permits parts fabrication by adding multiple layers of material.

This approach is called Additive Manufacturing (AM), contrary to the typical subtractive manufacturing methods such as engraving. The AM technique was born 20+ years ago, although it was used for a different course. Manufacturers utilized it for limited applications such as rapid prototyping.

Technological advancement has enabled manufacturers to create parts with improved geometrics and mechanical properties. Traditional manufacturing techniques couldn’t achieve this. Specific AM approaches have made it possible for manufacturers to manufacture objects using complex forms and materials reliably.

The aerospace and energy sectors have made significant steps in using this technology. Applications in electronics, food industries, and the medical sector are also significantly progressing. For instance, in 2016, GE Aviation launched an entire division dedicated to AM and is already using the technique for the rapid production of parts of its turbines. On the other hand, Siemens uses AM to steam turbines and build gas.

Metal 3D Manufacturing Processes

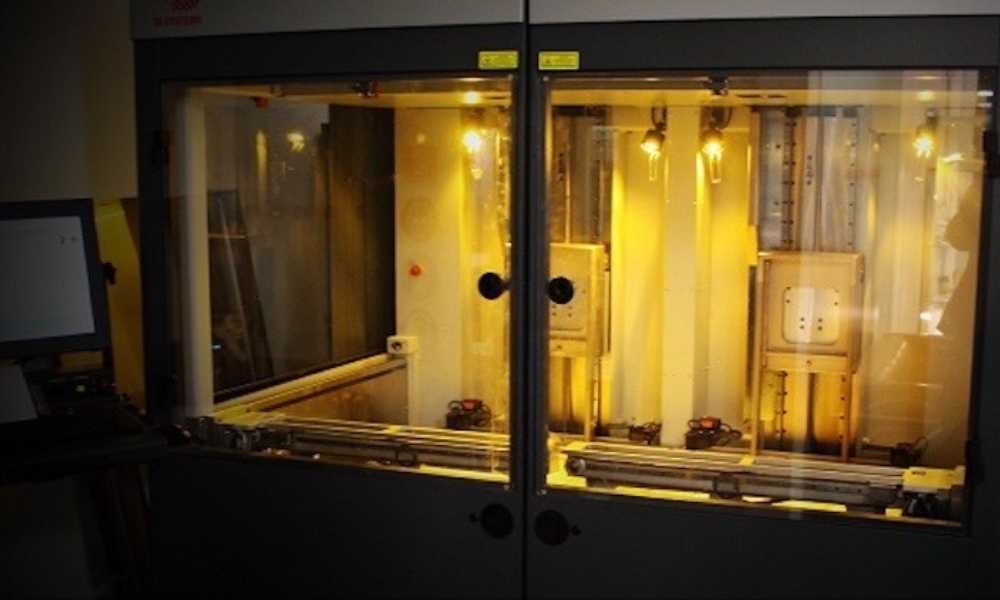

There are two primary techniques for metal 3D printing: Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM). They are both powder bed fusion 3D printing techniques. Although these two technologies might have their differences, they ideally use the same approach.

Some similarities include scanning and selectively melting or fusing metal powder particles using a laser, bonding them, and building parts layer-by-layer. They also use granulated metals for the procedures. The difference between DMLS and SLM comes from the particle bonding process and patents. SLM uses metal powders with constant melting temperatures to completely dissolve the particles, while DMLS uses metal powders with variable melting points that fuse molecularly at elevated temperatures.

There are other AM techniques, such as Ultrasonic Additive Manufacturing (UAM), Electron Beam Melting (EBM), Laser Metal Deposition (LMD), Selective Laser Sintering (SLS), Binder Jetting, and Metal Injection Moulding. However, their applications and availability are limited.

So, what is involved in a metal 3D manufacturing process?

- Fill the build chamber with an inert gas like argon to minimize the metal powder’s oxidationSpread a thin layer of the metal powder over the build platform.

- Scan the cross-section of the component using a high-power laser

- Heat the metal powder to its optimal build temperature.

- Fuse or melt the metal particles together to create the next layer

- Scan the whole area of the model to ensure it is fully solid

- Move the build platforms downwards by a single-layer thickness.

- Repeat the entire process until the part is complete

- Cool the bin to room temperature

- Remove the components from the build plate and prepare for post-processing.

- Manually remove the excess powder.

- Heat-treat the parts to relieve any residual stresses

- Perform further post-processing depending on the order

What Characterizes Metal 3D Printing?

The several aspects that characterize the entire metal 3D printing procedure and mechanism include;

DMLS and SLM Printer Parameters

The machine’s manufacturer sets nearly every process parameter in DMLS and SLM. The layer height varies from 20 to 50 microns in metal 3D printing. This depends on the metal powder properties, such as shape, flowability, and particle size distribution.

A standard metal 3D printing system measures 250 x 150 x 150 mm, but larger configurations measure up to 500 x 280 x 360 mm. A metal 3D printer can achieve a dimensional accuracy of approximately ± 0.1 mm.

Parts of a metal 3D printer are attached to the build platform, which restricts the available print area to an XY direction. The metal powder used in the various techniques is highly recyclable, as a maximum of 5% is wasted.

Part Orientation and Support Structures

Part orientation is conducted at an angle to maximize strength in critical directions and limit the probability of warping. However, this increases the quantity of required support, material waste, build time, and, eventually, the total cost.

Support structures are vital because of the extreme processing temperatures and distinct lattice patterns. Support structures are meant to;

- Offer a conducive platform for the preceding layer to be built upon

- Prevent warping by anchoring the part to the build platform

- Draw heat away from the worked-on part to facilitate a controlled cooling rate.

Layer Adhesion

DMLS and SLM parts have nearly isotropic thermal and mechanical properties. They are solid with minimal internal porosity of less than 0.2 – 0.5% in their as-printed state and practically null after thermal processing. Metal 3D printing parts are more flexible, more complex, and stronger than those manufactured with the traditional method. However, they are vulnerable to fatigue.

Lightweight Structures and Hollow Sections

Using the lattice structure is an ordinary approach in metal 3D printing to reduce parts’ weight. Topology optimization algorithms are also helpful in designing lightweight organic forms. Solid support structures enable hollow sections in metal printing as parts aren’t easily movable.

What Common Materials are Used for 3D Metal Printing?

3D metal printing uses different metals to facilitate various applications. The various are fully functional prototyping and creating production tools for inserts or molds, heat exchangers, heatsinks, ductwork, and housings. The common materials for 3D metal printing include;

- Stainless steel – Excellent for objects exposed to steam, water, or corrosive liquids because of its impressive corrosion resistance

- Gold – Best for printing jewelry

- Aluminum – Perfect for metal objects, ideally where lightweight is necessary, like with airframe parts

- Bronze – Ideal for marine propellers, pump impellors, fixtures, and decorative items like vases

- Nickel – Would suit printing of coin or turbine engine parts

- Titanium – A classic for producing solid and accurate parts like medical implants.

Check out: T-Shirt Printing Machine: Factors to Consider When Buying

Post-Processing Methods for Metal 3D Printing

Post-processing techniques are instrumental in improving metal printed parts’ accuracy, appearance, and mechanical properties. The mandatory post-processing steps involve removing the support structures and loose powder. Thermal annealing is usually deployed to improve mechanical properties and relieve residual stresses.

You’ll have to make dimensionally crucial features like threads and holes for specific orders. This is where the CNC metal machining service comes in handy. Furthermore, metal plating, micro-machining, media blasting, and polishing can come in handy to improve the fatigue strength and surface quality of the metal printed part.

What are the Benefits & Limitations of Metal 3D Printing?

Metal 3D printing has been effective and efficient as new and alternative technology. However, there are pros and cons to using metal 3D printing.

Pros

- Easy and fast to manufacture complexly-shaped items

- The capability to produce highly detailed and precise objects

- It doesn’t compromise on strength, even for complicated forms and lighter objects

- Reduces assembly costs and part counts as it can combine multiple parts of a complex object into a single component

- Cheaper than other conventional manufacturing methods

- It saves time and money since you can include details while assembling

- Minimal material wastage.

Cons

- Slow in producing traditional manufacturing-oriented parts

- Metal 3D printers are costly.

- Offers lower tolerance and precision than specialized CNC machining

- You’d require technical CNC machining services to design complex 3D metal parts.

- Powdered metal materials are relatively more expensive than non-powdered materials.

- Post-processing, heat treatment, and surface finishing are necessary.

- The build volume of a metal 3D printer limits parts sizes.

Check out: 3D Printing at Its Peak: First 3D Printed Heart Declared