A fuel pump is a mechanical or electrical device installed next to a car’s engine. The fuel pump is responsible for pumping fuel from the fuel tank to the engine. Therefore, in vehicles or other vehicles equipped with internal combustion engines, the fuel pump is the main requirement for pumping gas into the engine’s fuel tank. The fuel pump works with the carburettor to supply fuel to the fuel tank.

These Types of pumps take fuel from the fuel tank and deliver it to the engine via a fuel hose. When the gas reaches the machine, it injects directly into the combustion chamber or the intake manifold.

How does a Fuel Pump work?

Modern electric fuel pumps typically use the speed of the rotating turbine to draw fuel from the bottom of the fuel tank. The fuel then flows through the pump and enters the fuel line. The pump uses a system of pressure relief valves to precisely manage the fuel pressure.

The fuel pump is in the fuel tank and is submerged in fuel, which looks odd. This is possible because the fuel is poorly conductive.

Reasons for Fuel Pump Failure

Following are the significant reasons for the fuel pump failure:

Premature wear due to overheating the engine can be kept cold for a long time. When the fuel tank is low, the fuel pump does not sink, so there is less cooling. You also have to work harder to generate pressure, which causes the pump to heat up. The best way to avoid this problem is always to fill the tank and never go below 1/4 of the tank.

1. Gas exhaust failure

Once the gas is completely exhausted, it can damage the fuel pump. No gas, lubricant, or refrigerant. If you run out of gas, quickly turn off the ignition. Most fuel pumps operate when the ignition switch is turned on, even when the engine is not running.

2. Pump Corrosion Failure

If the car is fully packed with the fuel tank simultaneously, corrosion of the pump can occur. Ethanol absorbs water from the air and sweeps the water out of the pump. (Most gasoline contains ethanol.) To avoid this problem when storing your car, you can:

- The water tank is empty.

- Refine the fuel with additives that help prevent water buildup.

Check out: Different Types of Positive Displacement Pumps?

Type of fuel pump

Several types of fuel pumps are used in modern vehicles.

1.Mechanical Fuel Pump

The mechanical fuel pump is driven by an eccentric wheel on the engine’s camshaft. The engine block is installed on the side of the line. In some V-8 engines, it is installed between two cylinders.

AC mechanical fuel pump that screws into the engine block or crankshaft so that the rocker arm slides in front of the gear towards the pump motor or camshaft.

Includes a high-quality rubber impregnated cotton diaphragm. The diaphragm moves the fuel out of the tank and pushes it into the carburettor. When the cam turns, it moves and pushes the opening up and down. The downward movement of the membrane draws fuel from the tank through the filter. Moving the membrane upward pushes the fuel upward, closing the inlet and opening the outlet. Fuel enters the carburettor through the outlet valve.

If the carburettor float is full, there is no need to pump fuel until some part of it runs out, and the engine continues to run; the pump exerts an intense pressure on it which can damage the pump itself. As the fuel pressure in the pump increases, it compresses the diaphragm spring and rocker spring so that the rocker arm separates from the eccentric wheel.

Therefore, despite the continuous operation of the cam, the pump will not work until the fuel pressure on it decreases. In this way, the fuel source of the carburettor is adjusted to suit your needs.

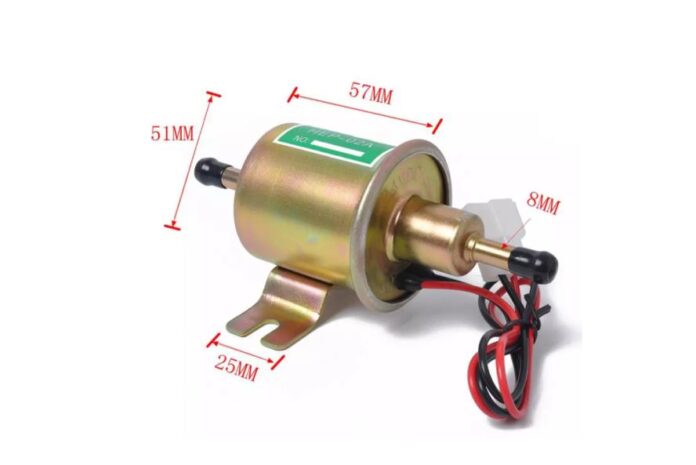

2. Electric fuel pump

It is the most common type of pump which uses in almost all vehicles. The electric fuel pump is installed in the fuel tank. This includes a propeller driven by an electric motor. It directs this fuel to the carburettor through the fuel line. Another electric service station is installed in the engine compartment. It also contains a diaphragm but works electrically. But when the ignition switch is turned on, the electric coil generates a magnetic flux drawn into the armature, and the diaphragm moves upwards.

The upward movement of the diaphragm creates suction, and fuel is drawn into the chamber through the inlet valve. But as soon as the armature moves, the power turns off, magnetic flux is lost, and the armature collapses, causing the inlet valve to open and close.

Fuel leaks into the carburettor. The downward movement of the armature restores voltage to the solenoid valve, and the same process is repeated, and the pump continues to run until the switch is turned off.