A rotary compressor is a mechanical device used to continuously flow a large volume of air at a pressure of up to 10 bar.

How does a Rotary Compressor Work?

A rotary compressor is a type of positive displacement compressor. As the name suggests, the rotary compressor produces compressed liquid coolant by turning the blades or moving the roller attached to the crankshaft off-centre. Since the rotational compressor voltage is so small, its volumetric efficiency is higher than that of a reciprocating compressor. Usually, the main gearbox (motor) and the compressor are installed in the same cylinder, and there is no gap between the compressor and the cover. That’s why they are small and light. One of the essential features of a rotary compressor is that it does not have an intake and exhaust valve used to replace the compressor.

Types of Rotary Compressor

The rotary compressors have the following major types:

1.Rotary Screw Compressors

It is an important type of compressor market today. Inside the unit, two large screws rotate in a connected way. Air enters through the inlet air at the end of the screw and then flows between the two rotors. As it moves along the screw, the air gap tightens and tightens, compressing the air towards the outlet.

These compressors are very popular because they are quiet and can produce a lot of air continuously. Plus, they come in a variety of forms, including oil-free options, which reduce the amount of maintenance required to keep the compressor running. Since the two bolts don’t touch, there’s hardly any abrasion other than the engine itself.

2. Scroll Compressors

Scroll compressors are similar to screw compressors, but their internal appearance is somewhat unique. In this case, there are two spirals or pulleys, one of which remains fixed. Before entering the centre of the outlet, the air enters the outer edge of the roll and is drawn into the centre of the roll into narrower loops. These compressors require minimal maintenance and are considerably smaller than screw compressors, making them suitable for applications in confined spaces.

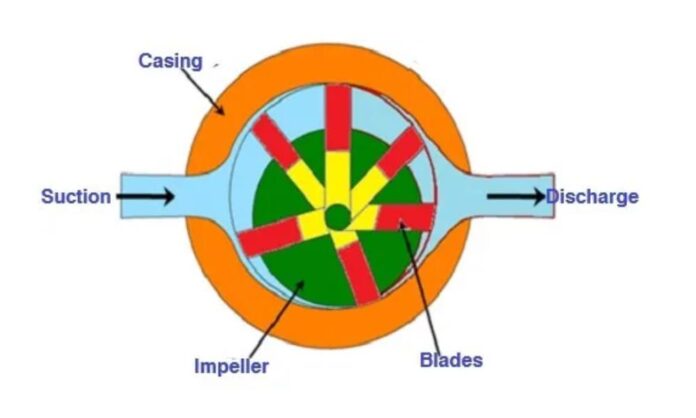

3. Vane Compressor

The third type of rotary compressor is the vane compressor. This system uses a series of blades that move slightly in the cavity. As air enters through the inlet, the rotating blades push the air to the edge of the narrowest circle. This process results in compression, using minimal force and blow. These compressors are very simple and easy to maintain. With time, the vanes disappear, and the efficiency of introducing air into the compression space decreases. In many cases, the blades can be replaced every few years to return the compressor to its original tolerance.

4. Lobe Compressor

The lobe compressor uses the same model as the vane compressor, except that the air enters the chamber with two rotating wheels. Small pockets are cut at both ends of the spinning wheel. As air enters, it fills the pocket and then blows into the chamber, forcing it to be compressed into a confined space. This is just the lowest wear resistance of a vane compressor which is reasonably priced and easy to use. However, lobe compressors have capacity limitations, so they may not be suitable for applications that require high pressure and constant airflow.

Check out: What is a Positive Displacement Compressor?

Advantages and disadvantages of rotary compressor

Advantages

- The rotary compressor is compact and lightweight.

- Do not exert any force or vibration without the replacement compressor. So, you don’t need an exact basis.

- High volumetric efficiency since customs clearance of the rotary compressor is very low.

- It works at high speed so that it can withstand a lot of liquids.

- Adequate weight of the machine parts. The noise is low.

- Low duration.

- Simple lubrication, no contamination/oil in the liquid outlet.

- Unlike frequently reciprocating compressors, rotary compressors constantly supply compressed air.

- Low initial cost.

Disadvantages

- Compared to a reciprocating compressor, the discharge pressure of each stage is lower.

- Not flexible in terms of capacity and compression ratio. More expensive (major defect).

- Improving filtration and lubrication is more complex but generally not necessary for working with portable devices.

- Wind capacity and total energy tend to be below.

- High-powered portable devices can be used, but they are almost always heavy and expensive in terms of fuel.

Application of Rotary Compressors

Rotary compressors are commonly used when large volumes of pressurized liquids are required. For large-scale industrial applications, high-powered power tools (such as jacks and impact wrenches), air pumps, and blasting operations. It is used in areas that require a constant flow of liquids, such as automated food production and packaging plants.

These are the four main types of rotary compressors you will find today. Although vane compressors are inexpensive, screw and scroll compressors are preferred by many industrial operations because they can withstand more air and provide better overall compression.