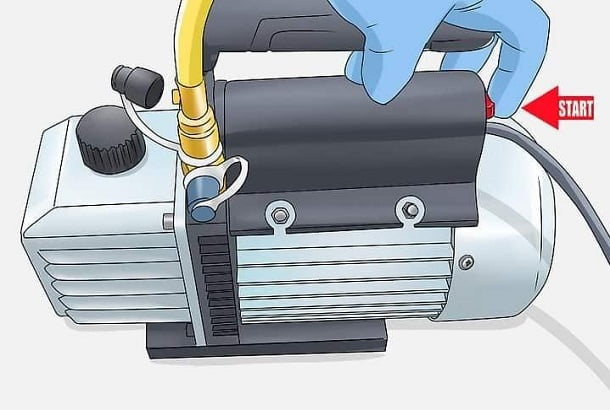

A vacuum pump is a device that extracts gas molecules from a sealed volume to generate a partial vacuum. The performance of the vacuum pump produces a relative vacuum in a given volume.

Working of Vacuum Pump

The working principle of the vacuum pump is that it draws air from the closed system by suction so that the density of the air in the confined space gradually decreases, and a vacuum can create. This removes air from the closed system because the mechanical energy of the rotating shaft is converted into pneumatic energy.

The level of internal force within the containment volume is less than the level of external force in the atmosphere. The energy produced depends mainly on the quantity of gas emitted, with the exception of air, and on the pressure difference between the internal and external atmosphere.

Types of Vacuum Pumps

1. Gas transform Pump

The pump delivers the gas molecules by exchange motion (dynamic action) or positive displacement. The number of gas molecules discharged from the pump equals the speed at which it enters the pump, and the gas pressure at the outlet is slightly above atmospheric pressure. The compression ratio is the exhaust pressure ratio (outlet) to the lowest pressure obtained (inlet).

2. Kinetic Transfer Pumps

The transmission pump uses the introduced high speed or steam blades to direct the gas to the outlet, and its principle of operation is the transmission of impulses. These types of pumps can achieve high compression ratios at low pressures but generally do not have a sealed volume.

3. Diaphragm Pump

A diaphragm pump is a favourite type of vacuum pump. It uses two membranes that move backwards and forward for the compression or suction of the fluid.

4. Positive Displacement Pump

A pump that works by mechanically using a certain amount of gas and transferring it through a pump is called a positive displacement pump. It is usually designed in stages on a single push of the actuator. The separated volume is compressed into a smaller volume under higher pressure. Finally, the compressed gas is discharged into the next air or bomb. To create more vacuum and flow, two transfer pumps are usually used in series.

As mentioned above, positive displacement pumps are used to produce a low vacuum. This type of vacuum pump enlarges the cavity and causes gas to escape from the sealed chamber or the atmosphere. Subsequently, the cavity is sealed and released into the air. The principle of the vacuum pump is positive displacement: create a vacuum by expanding the volume of the container.

For example, a mechanism expands a small sealed cavity in a portable water pump to create a deep vacuum. Due to the pressure, some liquid is pushed out of the chamber into the small cavity of the pump. The pump cavity is then sealed in the chamber, opened to air and then slightly compressed again. Another example of positive displacement of the vacuum is the muscles of the diaphragm, which dilate the chest cavity and increase lung volume. This expansion causes a slight partial vacuum and a decrease in pressure, which is then filled with air at atmospheric pressure. Examples of volumetric Vacuum Pumps are liquid ring vacuum pumps and root blowers, widely used in various industries to produce vacuum in confined spaces.

Advantages

The vacuum pump has the following advantages:

- These pumps are used for the safe pumping and transfer of waste from extraction fields.

- It has the ability to prevent leakage and odour control, making the transport of biocides easy and safe. The primary purpose of these pumps is to safely transport hazardous materials to protect the environment from toxic waste.

- Quickly remove debris from clogged drainage systems, save time and do things ahead of time.

- Used in jet engines, evacuation tanks and tailgates and ideal for a wide range of applications.

Disadvantages

The disadvantages of vacuum pumps include the following.

- The liquid lines can damage these pumps.

- The liquid and gas pump process must be perfectly adequate to prevent contamination.

- The liquid vapour can limit the suction pressure of the pump in the pump.

- Due to the vapour pressure of the sealing fluid, the vacuum achievable at the operating temperature can be limited.

Uses of the vacuum pumps

Applications of vacuum pumps include the following.

- These pumps are used in various industrial and scientific processes, including complex plastic moulding, vacuum tubes, CRT, lamp manufacturing, semiconductor processing, dry etching, especially ion implantation and positioning of ALD, PVD, CVD and PECVD in lithography and many others.

- The vacuum pump uses to support the machine equipment. For example, the pump can be installed in the engine of a diesel or hybrid vehicle.

- The pump can be used to power automotive components such as hydraulic brakes, shock absorbers, gas actuators and doors.

- These pumps are used in aircraft and often use vacuum sources to control gyroscopes in various aeronautical instruments.

- The instrument panel can prevent the device from being completely lost in the event of a power failure. The dashboard is designed to be a special instrument and other instruments powered by a vacuum source.

Check out: What is a Jet Pump? Types and Applications