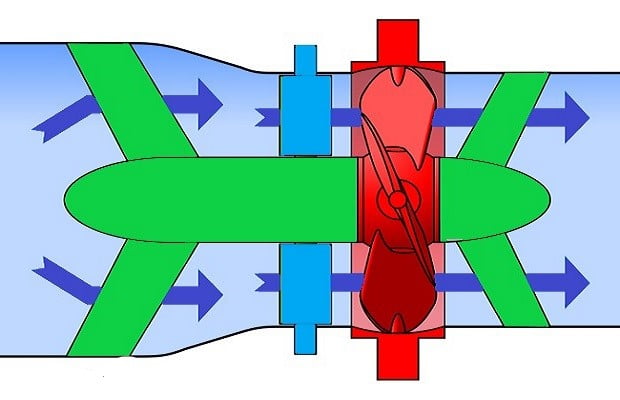

A reaction turbine is a type of turbine that can generate the torque based on pressure or mass of a liquid. The reaction action of a turbine force is described by Newton’s third law of motion (the action of the force and the reaction force are equal and opposite). The reaction turbine working is different from than impulse turbine.

In a reaction turbine, pressurized water enters the impeller and flows through the vanes. As running water is pressurized through the blades, the turbine wheel runs at full load and can sink under the exhaust pipe or drain into the air. The water head becomes a speed head as it passes through the blades, and eventually, the atmospheric pressure drops before the impeller starts.

Parts of Reaction Turbine

1. Spiral casing

The water in the pipe distributes through the chamber guide ring. The casing design reduces the cross-section evenly around the perimeter. The cross-section at the entry is the largest and the smallest. Therefore, this chamber will be a spiral chamber or a spiral chamber.

2. Guide mechanism

The van rails fix between two ring wheels. It is fixed with a spiral sleeve. Guides suitable for:

- Let the water enter the corridor without any effect.

- Let the water flow through them without vortex.

- Let the required amount of water enter the turbine.

All steering vans can rotate around their separate axes, which are attached to the fixed ring of some mechanical devices. The fixed ring is connected to the fixed rod by two fixed rods.

By operating the adjustment shaft, the driving vans can be closed or opened so that the necessary amount of water can flow if necessary. The governor drives the governor shaft, and its job is to control the turbine (i.e., maintain a constant speed when changing loads).

3. Turbine Rotor

The reaction turbine rotor includes rotor blades that rely on the shaft depending on the kind of turbine. These paddles are designed to permit water to go into and go out of the rotor without being affected. The rotor connects to the shaft, and the shaft may be vertical or horizontal. If the axis is vertical, it’s far known as a vertical turbine. Similarly, if the axis is horizontal, it’s far known as a horizontal turbine. The surface may be very smooth. The rotor may be forged in a single piece, made on separate metallic plates, and welded together. For the decreased head, the rotor may be made from forged iron. But for the long head, the rotor is crafted from metallic or alloy. When the water isn’t always chemically clean, the rotor is made from a unique alloy.

4. Draft Tube

The water passes through the tube, goes down a pipe called a suction pipe. It usually locates about 1 meter below the waterline of the tail. The function of the draft tube is following.

- Raise the height of the water, and the rise equals the height of the channel outlet at the top of the drain pipe.

- Improve turbine efficiency.

Classes of Reaction Turbine

1. Radial flow turbines

In these turbines, water flows radially (i.e., along with the radius of the wheel). The radial flow turbines may be further sub-divided into two classes:

(a) Inward Flow Turbines

· In this type of turbine, water enters the wheel from the outside and then flows inwards (i.e., towards the center of the wheel).

- Here guide mechanism surrounds the flow path.

- In this type of turbine, the outside diameter is the inlet impeller, and the inside diameter is the outlet.

(b) Outward Flow turbine

- In this reaction turbine, water enters and then outward flow (i.e., around the wheel).

- Here rotor surrounds the guide mechanism.

2. Axial Flow Turbines

In these turbines, the water flows parallel to the axis of the wheel.

Types of Reaction Turbine in Axial Flow Turbine

Mixed Flow Turbines

These are the modern type of turbines, in which the water flow is partly radial and partly axial such as Francis turbine.

Pros and Cons of Reaction Turbine

Pros

- Reactive steam turbines can be used for high-temperature and high-pressure steam.

- High efficiency of the blade.

- By positioning the blade, both the compressive force and the moving (working) force are available.

Cons

- It needs more space for each unit of energy produced.

- The housing must be sealed.

- Compared to fast turbines, it has more vapor losses

Usages

- Reaction turbine uses to generate electricity in wind farms

- The most used turbine in hydroelectric power plants to generate electricity.

- Aside from the inefficient cross-flow turbine, this is the only turbine that can get the maximum output power from an existing low and high-speed head.

Check out: What is a Centrifugal Pump? Working and Components