A Kaplan turbine is a propeller turbine that is used in hydroelectric power plants. It is the most common and famous type of reaction turbine. Water enters and leaves the Kaplan turbine through the rotating shaft, which is known as axial flow. The impeller blades of these turbines can change the angle to maintain maximum efficiency in different water flows. Due to this reason, these turbines are the most popular.

The Kaplan turbine is similar to the Francis turbine, but their working is different from each other. The water flowing through the Kaplan turbine loses pressure.

The area in which water can supply to these turbines is large and corresponds to the total space that the blades take up. The large surface area of the Kaplan turbine makes it more useful even with relatively low dams that can consume large amounts of water. This was particularly noteworthy before the development of the Kaplan turbines; most turbines were only suitable for high heads.

The construction of these turbines allows a large amount of water without being damaged the turbine. These turbines are designed slightly differently than other turbines. The Kaplan turbines are much quieter than other reaction turbines. There is a flow channel for water injection in the radial direction, and functional guide vanes can direct the water suddenly into the turbine in the axial direction.

Check out: Five Best PVC Pipe Manufacturers in India

Components of Kaplan Turbine

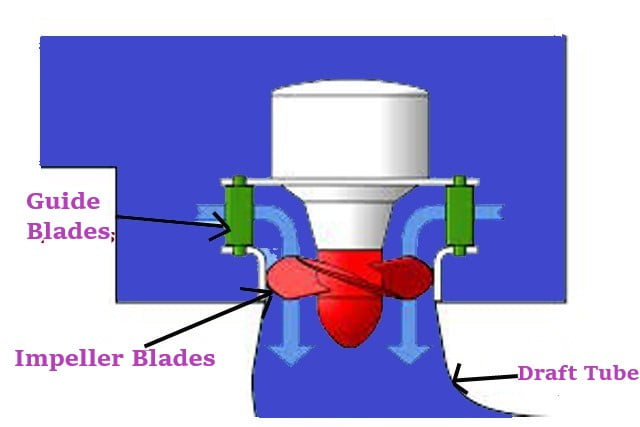

The Kaplan turbines have the following major parts:

- Scroll casing

- Guide vane mechanism

- Draft tube

- Runner blades

1. Scroll Casing

It is a spiral pattern with a reduced cross-sectional area. The water from the pressure pipe first enters into the scroll casing, and then the guide vanes. The guide blades turn the water angle up to 90° and flow through the passage in the axial direction. This component of the Kaplan turbine prevents the guide blades, impeller, impeller blades, and other internal turbine parts from destruction outside the turbine. It also prevents the internal parts if any heavy load falls on the turbine.

2. Guide vane

The guide vane mechanism is a unique control part of the entire turbine that closes and opens according to the power requirement. When the power requirements are high, the guide vans open wider so that more water can flow into the impeller’s blades. As the requirements of the power become low, it will turn off to discontinue the water flow. If your turbine has no guide vane, the turbine can’t operate efficiently; this decreases the turbine efficiency.

3. Draft Tube

At the exit of the turbine duct, the public pressure is usually below compared to atmospheric pressure. Therefore, the discharge water can’t transfer directly into the tailrace.

The tube can gradually increase the area used for drainage from the turbine to the exhaust pipe.

Therefore, the increasing area of the pipe is also known as the draft pipe. One side of the draft pipe connects to the outlet of the runner, and the other end dips below the water level of the exhaust pipe.

4. Runner Blade

The heart of the Kaplan turbine component is its blade because it is a rotating component that helps generate electricity. These blades rotate with the runner rotation. The runner shaft connects the generator shaft. The turbine runner has a large hub, and its blades fix on the hub. These blades can adjust to the best angle of attack for maximum performance. Kaplan turbine blades can twist along their axis.

Working of Kaplan Turbine

Firstly, the water introduces from penstock into the Kaplan turbine. The spiral casing of the turbine manufactures in the desired shape so that the flow pressure can’t be lost. Next, the guide vanes direct the water into the rotor blades. The paddles are adjustable and can be adjusted depending on the flow requirements. The water rotates 90 degrees, so the direction of the water and the direction of the blades are axial.

Due to the reaction force of the water, the blades of the impeller begin to spin when the water hits. The impeller blade twists along its length so that all cross-sections of the blades always have the best angle of attack, and thus a higher efficiency is achieved. Water goes in the intake manifold from the blades, where its kinetic and pressure energies gradually decrease. The conversion of kinetic energy into pressure energy leads to a rise in water pressure. The turbine rotation is used to turn the generator shaft to produce electricity.

Application of Kaplan Turbine

- Kaplan turbines use around the world to generate electricity.

- Compared to other types of turbines, they can work more efficiently at low heads and high flow rates.

- It’s more minor and easy to build.

- Compared to other turbines, Kaplan turbines are very efficient.

Advantages of the Kaplan Turbine:

- Compared to other turbines, this type of turbine works more efficiently at low head and high flow.

- The size is smaller.

- Compared to other types of turbines, Kaplan turbines have more efficiency.

- These turbines have an easy construction

- A Kaplan turbine needs a low area

Disadvantages

- The axis position is only possible in the vertical direction.

- It requires a significant water flow for operation.

- These turbines have cavitation issues. This happens due to the pressure drop in the drain pipe.

Check out: Types of Renewable Energy Sources, resources, Pros and Cons